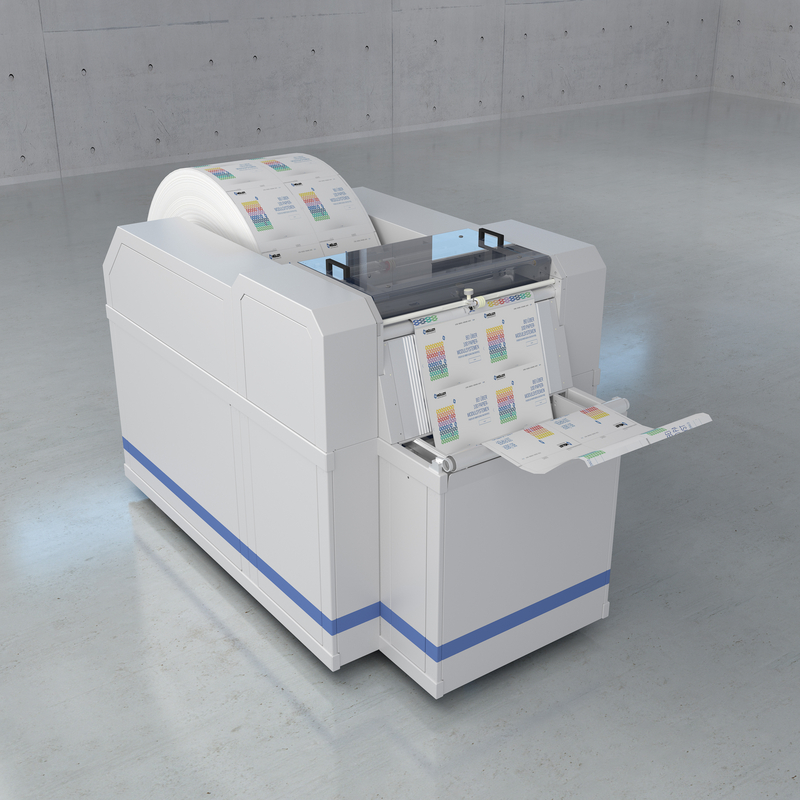

The Müller 6700 web cutting system fulfills all requirements for transaction applications and the graphic market. Easy and flexible to use, it is one of the leading systems in the industry. With all its features it is the optimal system for complex applications. The Müller 6700 utilizes the printing and paper width of 22“ inkjet printing systems 100 percent. Variable paper lengths are possible at any time. This makes the web cutting system the best choice – even for book-of-one applications. With a 1-up and 2-up offset stack (with and without a cut-out), it gets the maximum out of each paper web.

As a stand-alone or as a complete online solution integrated into a digital printing line with the Müller web buffer – the Müller 6700 can be used flexibly. And thanks to the new non-stop stacker, even small stacks can be processed online. The variable high-performance cutting system is upgradable in all directions. Camera job control, dynamic perforation or file hole punching are common options.

150-Meter-Class • horizontal and vertical trim at full speed

White-Paper-Management • blank web (macule) will be diverted without stop

Processing-Flexibility • pinless or pinfeed, 1-up and 2-up

Process-Control • document monitoring and camera job control

Ease-of-Use • integrated Müller product concept

Simple handling through full automated, large web buffer and intuitive operation: The unwinder processes paper rolls up to a width of 560 mm and is up to 240 m / min. fast. The automatic clutch for the paper roll shaft speeds up the paper reloading process. Different sized web buffers can be chosen for special applications. Operation is possible with or without paper tension.

Highly stable paper path, running up to 50,000 documents in A4 per hour. Multi gains up to 2-up can be processed at a web width of 560 mm. Gross formats will be cropped 4-sided to the net format. The cutter works at the horizontal (slit and gutter cut) and vertical cuts at full speed. Waste sheets will divert by the whitepaper-management. The use of highly durable knives allows long maintenance intervals.

The grouped documents are accelerated and placed on the stacker separated into groups. The stacks can be deposited on the delivery belt without getting caught up in one another. It is therefore easy for the operator to remove the stacks. When the end of the stack is reached, the stacks are passed onto the next delivery belt. Through an integrated clipboard the system works also while stack exchange without interruption. The height of the stack is around 2,000 sheets at 80 g/m².

| Performance |

50.000 Documents/h (125 m/min at A4) Pinless or pinfeed |

| Paper |

80 - 160 (200) g/m² 140 - 560 mm (5 1/2 - 22'') paper width* 140 - 500 mm (5 1/2 - 20'') paper length* |

| Usage |

1-up and 2-up White-Paper-Management (e.g. for inkjet printers) Parallel print |

| Cutter |

Horizontal slit- and gutter-cut at full speed Vertical slit- and gutter-cut (left, right, within the document) |

| Stacker |

Stack up to 2,000 sheets (80 g/m²) Group seperation via reading or counter |

| Interface |

Document-monitoring Interface for production management systems (PMS) |

| Options |

Web Buffer 20 meters for online connection Dynamic perforator Transport paper stack to the next module |

| * Special dimensions are available on request |